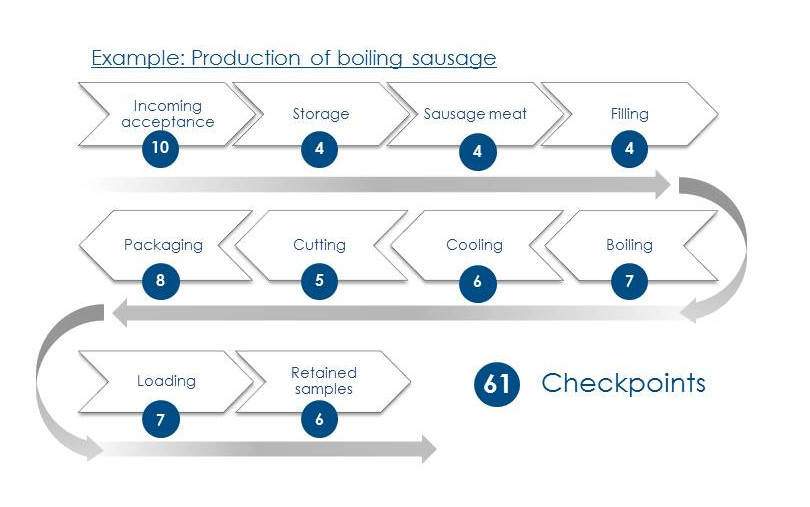

Every article passes 61 in-house checkpoints

At zur Mühlen Group we use state-of-the-art technologies and methods during the quality tests, in order to ensure the high quality of raw materials and the safety of our products. The production itself is reviewed in risk analyses in order to find and exclude product risks by applying clear and strict rules. All products undergo regular testing and analyses at in-house and independent external laboratories. More than 50,000 tests in total are carried out each year. From receipt of the raw materials to manufacturing and delivery, each article passes 61 in-house checkpoints. This is how the zur Mühlen Group ensures the high standard of quality